Textile architecture

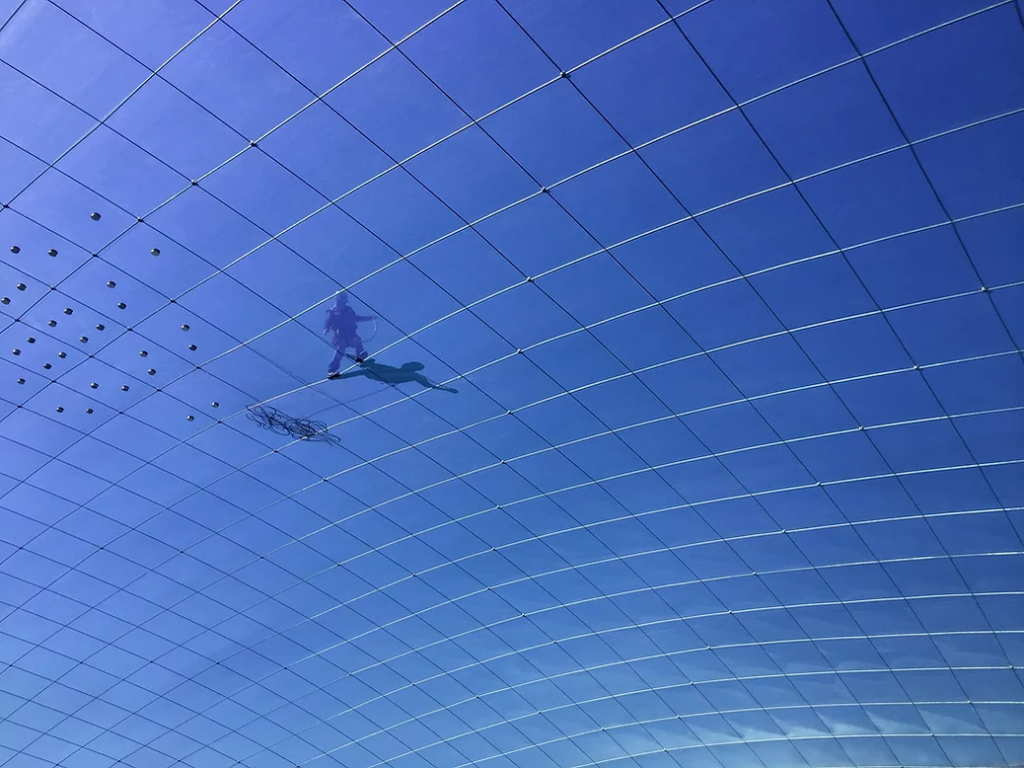

Tensile, fabric canopies are by no means only suitable for temporary structures. They are fully-fledged constructions that are able to withstand all adverse weather conditions such as wind and snow. The organic form with a double curvature is not just functionally necessary, it also gives fabric structures their unique appearance.

Organic forms are in vogue – tensile fabric structures are distinguished by their floating forms, but these are not randomly configured by the architect; they follow natural principles that result in elegant, flowing contours.

In recent years much research has gone into the building techniques for fabric structures. Comprehensive software is now available for reliably determining both the form and the structural properties. Fabric architecture has been embraced by the industry and as a result, numerous textile manufacturers now offer a wide range of materials that can be selected according to specific requirements. The lifespan of these materials is usually around 25 to 35 years.

From very small structures to stadium roofs, the scope of tensile fabric architecture is extremely broad. Membranes can be used as façade elements as well as interior structures.

Fabric architecture has a very particular style in which form, structure, and detail are closely intertwined. The desire for architectural authenticity is almost automatically fulfilled – the supporting framework defines the structure’s overall appearance. Details have both a structural and aesthetic function. 3dtex GmbH specialises in the design and realisation of such entities encompassing structure, design, and functionality.

The words ‘lightweight’ and ‘elegant’ are often used in connection with tensile fabric structures. Yet these attributes are not intrinsic, they have to be painstakingly worked on: choosing the right form, the arrangement of details, and the material quality are extremely important in this regard.