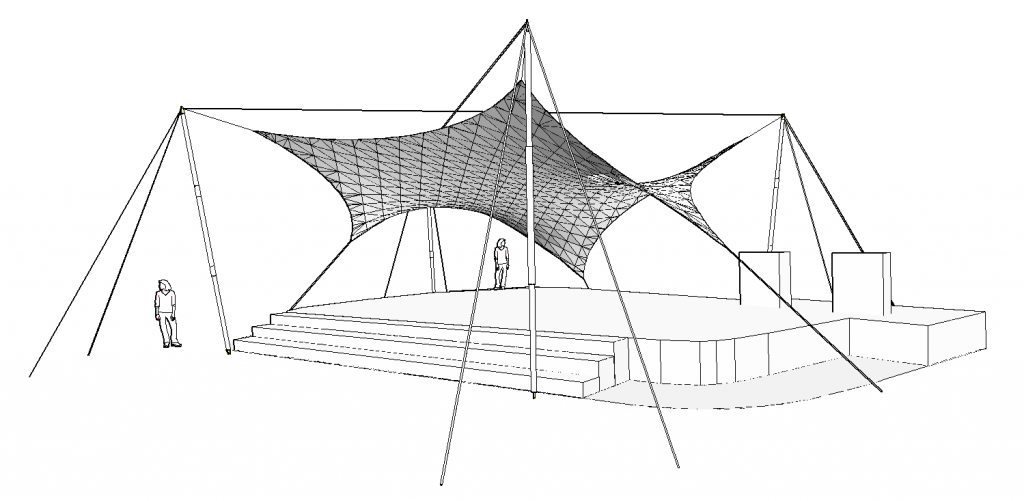

Our service for Textile Architecture and ETFE Construction

On all projects, 3dtex works with an established network of specialists, including membrane manufacturers, specialist engineers, material science laboratories and trained industrial climbers. At 3dtex GmbH all threads come together. As an expert in its field, 3dtex can guarantee the smooth running of a project from a technical, creative, and financial perspective, as well as its on-schedule completion. We offer:

- Strategic and conceptual consultancy, preliminary drafts, visualisations.

- Geometric definition of the three-dimensional form, structural analysis and engineering of the structural elements.

- Detail design, cutting patterns for the membrane, membrane detailing.

- Detail design, cutting patterns for the membrane, membrane detailing.

- Fabrication of all separate parts such as membranes, cables, steel constructions, fastening elements partly by external suppliers according to the specifications of and monitored by 3dtex GmbH.

- Project management and quality assurance.

- Delivery and assembly on site.

- High quality standards.

Our quality standards

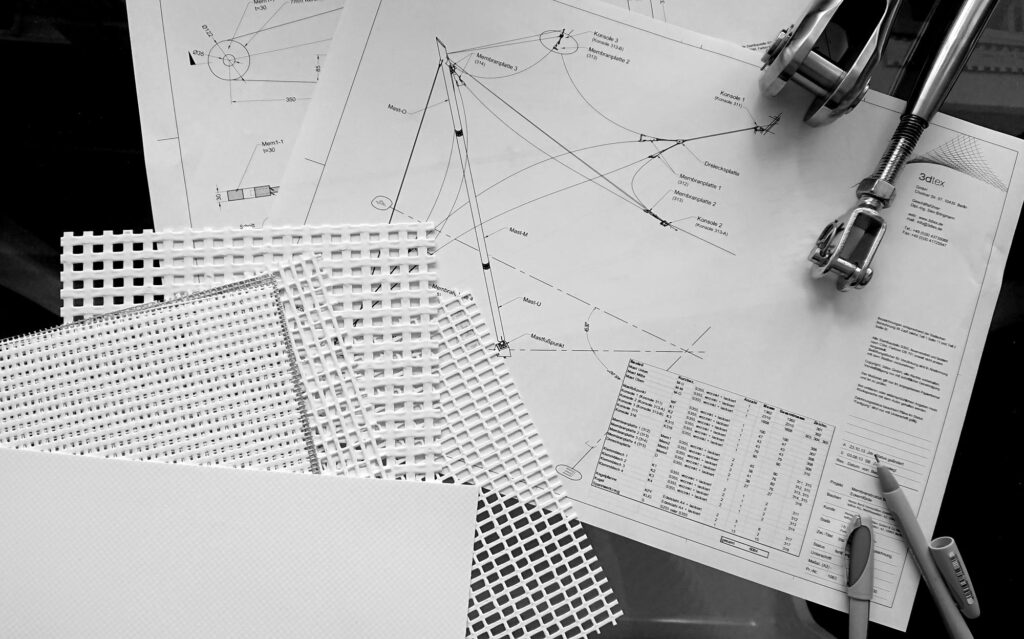

Focusing on the quality of every single structural element is vital for the overall quality and appearance of a fabric structure. That is why 3dtex GmbH pays particular attention to the selection and construction of the connecting elements in all projects. Edge cables, tension links and membrane plates usually are made from stainless steel. All fabrics used are made by European quality producers only.

All of the details are planned down to the millimeter in a virtual 3D model and tested before they are manufactured, mostly in Germany. Ongoing quality tests are also carried out at our suppliers’ yards to guarantee the highest quality.